Data center liquid cooling mainly has three deployment methods: cold plate, immersion, and spray. Cold plate liquid cooling is an indirect liquid cooling method, while immersion and spray are direct liquid cooling methods. In the cold plate liquid cooling system, heat-generating components do not come into direct contact with the liquid but transfer heat through cold plates filled with liquid (usually enclosed cavities made of conductive metals such as copper or aluminum), and then the liquid circulation carries away the heat. Since server chips and other heat-generating components do not need to come into direct contact with the liquid, the system does not require a complete redesign of the entire data center equipment, making it more operable. Therefore, cold plate liquid cooling is also the most mature and widely used of the two liquid cooling methods.

Universal Server CPU Liquid Cooling Kit

Technical Specification

| Chip Platform | Configuration | Materials | TDP(W) | SPEC Tcase(℃) | Designed Tcase(℃) | Outline Drawing | ||

|---|---|---|---|---|---|---|---|---|

| EGS | Flagship Edition | Cu | 350-400 | <61 | <58 | 10 | <0.024 |

|

| Standard Edition | AL(heat exchanger fins) | 200-300 | <74 | <65 | 10 | <0.062 | ||

| Basic Edition | AL(Extrusion Profile) | <200 | <70 | <65 | 10 | <0.081 | ||

| SP5 | Flagship Edition | Cu | 400-600 | <60 | <58 | 10 | <0.023 |

|

| Standard Edition | AL(heat exchanger fins) | 200-400 | <70 | <65 | 10 | <0.051 | ||

| Basic Edition | AL(Extrusion Profile) | <200 | <70 | <65 | 10 | <0.081 | ||

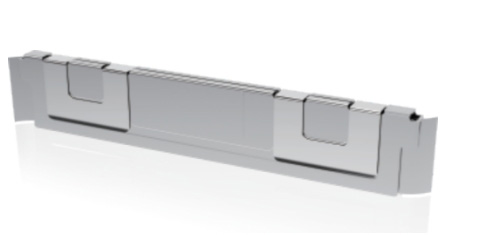

Storage Liquid Cooling Heat Dissipation Kit

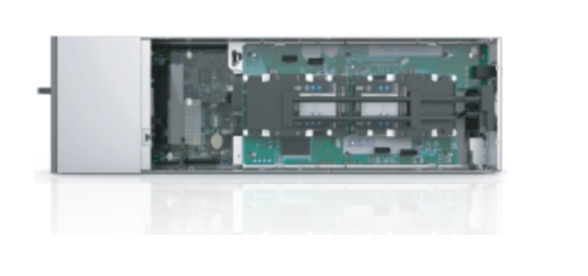

Blade Server CPU Liquid Cooling Heat Dissipation Kit

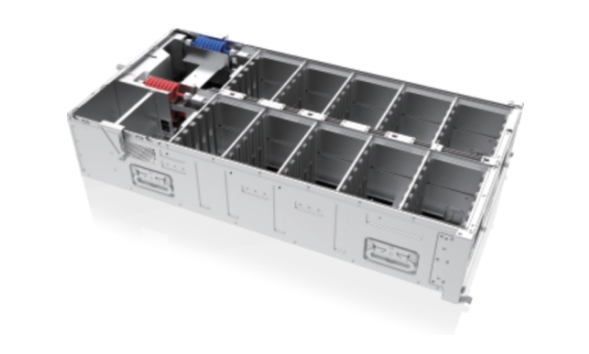

Rack Server Liquid Cooling Cold Plate Kit

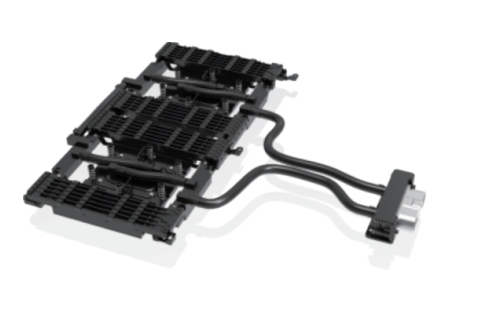

AI Server Liquid Cooling Cold Plate Heat Dissipation Kit

[ PCIe Card Form ]

[ NV- link Form ]

AI Server Liquid Cooling Cold Plate Heat Dissipation Kit

Cold Plate Liquid Cooling Server Diagnostic Equipment

Air Pressure Resistance Tester

Thermal and Flow Resistance

Tester Pulse Cleaning Equipment

Helium Mass Spectrometer Leak Detector

Technical Specification

| Test Items | Test Equipment | |

|---|---|---|

| Routine Testing | Dimension Inspection | 3D Dimensional Measurement |

| Flow Resistance Test | Flow Resistance Test Bench | |

| Air Tightness Test | He Testing Instrument | |

| Internal Cavity Cleanliness Test | Particle Counter | |

| Performance Testing | Thermal Resistance Test | Liquid Cooling Cabinet |

| Environmental Testing | Thermal Cycling Test | High-Low Temperature Test Chamber |

| High-Temperature Test | High-Low Temperature Test Chamber | |

| Salt Spray Test | Salt Spray Test Chamber | |

| Compatibility Test | Static Test Bench | |

| Mechanical Testing | Vibration Test | Vibration Test Bench |

| Torsional Vibration Test | Torsional Vibration Testing Platform | |

| Pressure Resistance Test | Hydraulic Pressure Burst Test Bench |

Fluid Connector

Cold plate liquid cooling servers utilize fluid connectors. A fluid connector is a type of joint that can establish or disconnect fluid pathways without the need for tools, preventing liquid leakage and supporting hot swapping of pipelines, ensuring that no coolant leaks during system installation or maintenance. Fluid connectors are selected based on different flow rates with varying diameter specifications; different materials are chosen based on fluid parameters; self-locking and blind mating forms are selected according to the system's locking method; and specific products are custom-developed based on special product requirements, etc.

| Types | UQD02 | UQD04 | UQD06 | UQD08 | UQDB04 | UQDB06 |

|---|---|---|---|---|---|---|

| Diameter | 3 | 5 | 7 | 10 | 5 | 7 |

| Flow Rate L/min | 1.65 | 5.5 | 10 | 15.1 | 5.5 | 10 |