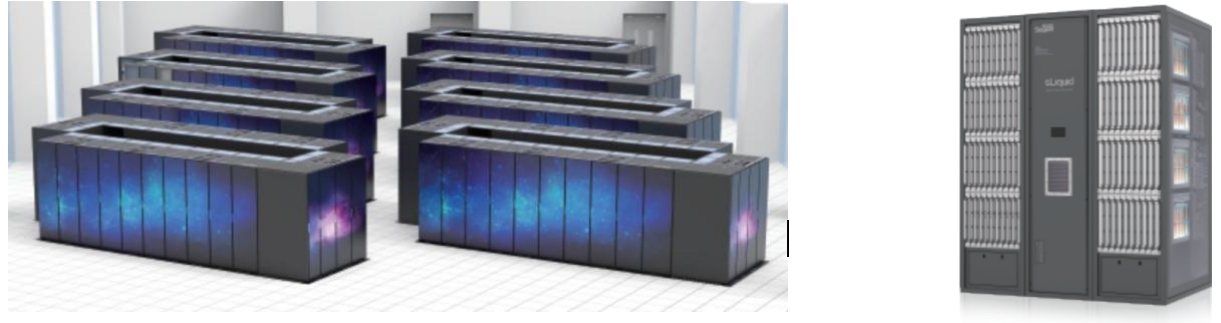

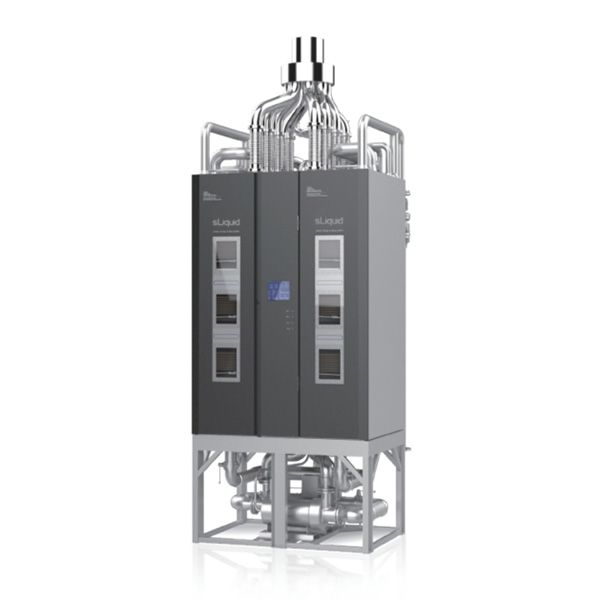

Phase-Change Immersion Liquid Cooling Infrastructure System C8000R-E420

Phase-Change Immersion Liquid Cooling Infrastructure System C8000R-E420 is a product developed by SLIQUID GLOBAL for data center environments. It is primarily used to provide efficient liquid cooling and high-voltage direct current power supply for ultra-high-density computing, featuring advantages such as high-density deployment, green energy saving, and low noise in the computer room.

The C8000R-E420 includes one Phase-Change Immersion Liquid Cooling Coolant Distribution Module (CDM) and two Phase-Change Immersion Liquid Cooling dedicated computer cabinets. Each CDM is equipped with one set of hydraulic regulation and coolant circulation module, and each computer cabinet is installed with one rack-mounted power distribution module.

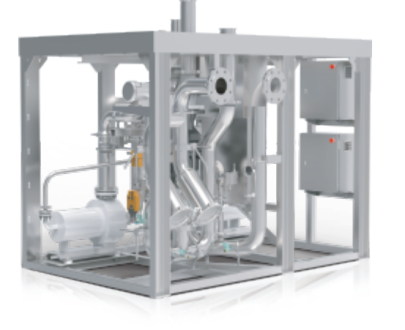

Phase-Change Immersion Liquid Cooling Infrastructure System C8000S-E1260

Phase-Change Immersion Liquid Cooling Infrastructure System C8000S-E1260 is a product developed by SLIQUID GLOBAL for environmental applications.

It is primarily used to provide efficient liquid cooling and high-voltage direct current power supply for ultra-high-density computing, featuring advantages such as three-dimensional deployment, centralized heat dissipation, and separation of electricity and water.

The C8000S-E1260 includes one Coolant Distribution Module (CDM) and three specialized trinity computer cabinets for immersion liquid cooling. Each specialized trinity computer cabinet for immersion liquid cooling can accommodate 80 immersion liquid-cooled blade servers and is equipped with integrated power distribution and coolant supply functions.

Technical Specification

| Phase-Change Immersion Liquid Cooling Infrastructure System |

C8000R-E420 | C8000S-E1260 |

|---|---|---|

| Included Modules | ① Immersion Liquid Cooling Dedicated Computer Cabinet ② CDM ③ Hydraulic Regulation and Coolant Circulation Module ④ Rack-Mounted Power Distribution Module |

① CDM ② Immersion Liquid Cooling Integrated Trinary Computer Cabinet |

| Application Scenarios | Flat Data Center | 3D Data Center |

| Maximum Supported Cabinet Quantity | 2 | 3 |

| Maximum Supported Server Quantity | 80 Pics | 240 Pics |

| Heat Exchange Capacity | 440kW | 1320kW |

| Display Cabinet Selection | The right-side cabinet can be configured as a display cabinet. | The right-side cabinet can be configured as a display cabinet. |

| Power Distribution System for Computer Cabinets | HVDC Power Distribution System | HVDC Power Distribution System |

| AC Power Distribution Requirements"(CDM Power Distribution Specifications) | 3ph-380Vac 50Hz; Five-wire system (3P+N+PE) for incoming lines, dual power supply; power distribution capacity is 4.5kW. |

3ph-380Vac 50Hz, Five-wire incoming line system (3P+N+PE), dual power supply; power distribution capacity is 20kW. |

| Auxiliary AC Access(PDM) | 220Vac 50Hz,Three-wire incoming line system(1P+N+PE) | 220Vac 50Hz,Three-wire incoming line system(1P+N+PE) |

| Secondary Side Coolant | Phase Change Immersion Server-Specific Electronic Fluorinated Fluid(SFM-5016N) | Phase Change Immersion Server-Specific Electronic Fluorinated Fluid(SFM-5016N) |

| Primary Side Coolant | Softened Water, Ethylene Glycol Water Solution | Softened Water, Ethylene Glycol Water Solution |

| Permissible Supply Water Temperature on the Primary Side | 15~35℃ | 15~35℃ |

| Maximum Inlet/Outlet Water Temperature Difference on the Primary Side | 8K(Under standard atmospheric pressure, calculated with softened water as the medium.) | |

| Rated Inlet/Outlet Water Temperature on the Primary Side | 33/41℃(Under standard atmospheric pressure, calculated with softened water as the medium. | 33/41℃(Under standard atmospheric pressure, calculated with softened water as the medium. |

| Rated Water Flow Rate on the Primary Side | 47.3m3/h(Under standard atmospheric pressure, calculated with softened water as the medium.); Supports infinite adjustment of flow rate from 10% to 100 | 双路71m3/h(Under standard atmospheric pressure, calculated with softened water as the medium.); Supports infinite adjustment of flow rate from 10% to 100% |

| Primary Side Pressure Resistance | 8bar | 8bar |

| Rated Hydraulic Requirement on the Primary Side | 1.2bar | 1.2bar |

Immersed liquid cooling Coolant Distribution Module (CDM)

Immersed liquid cooling Coolant Distribution Module (CDM) is the core heat exchange component of SLIQUID GLOBAL's immersion liquid cooling system. It uses water at 15-35°C as a cooling source to condense the gaseous coolant, achieving natural cooling throughout the year. The single device has a strong cooling capacity with a rated heat exchange capacity of 440-1320kW. It features ultra-low energy consumption, high cooling efficiency, low noise, and high reliability.

The liquid cooling heat exchange module mainly has the following three functions:

(1) Providing circulation power for the coolant

In the indoor circulation, the CDM provides circulation power for the entire liquid cooling system's coolant, ensuring continuous circulation of the coolant in the system, constantly removing the heat from the load.

(2) Controlling the temperature, pressure, and flow rate of the coolant in the circulation system

In the indoor circulation, the CDM is the control core of the entire system. All key point signals within the system are aggregated in the CDM. The CDM comprehensively analyzes the system's operating status and adjusts the total coolant flow rate, temperature, and pressure in the system according to predetermined strategies.

(3) Transferring the heat carried by the coolant to the outdoor side

At the same time, the CDM is also the physical connection point between the indoor and outdoor parts of the machine. The indoor and outdoor parts exchange heat through the CDM, and ultimately, the heat carried by the coolant, generated by the load, is efficiently transferred outdoors. Through the system circulation of the outdoor part, the heat is ultimately released into the natural environment.

| Immersed liquid cooling CDM | CDM-R-2420FM | CDM-S-21260FM |

|---|---|---|

| Overview | The module includes units such as purification, gas return, liquid supply, and liquid return, providing auxiliary functions such as heat exchange, working fluid purification, and circulation pipeline for the immersed liquid cooling system. | |

| Dimensions | Weidth700mm×Depth1400mm×Height2600mm | Weidth2000mm×Depth1972mm×Height5090mm |

| Rated heat exchange capacity | 440kW(Under Standard Atmospheric Conditions) | 660kW×2(Under Standard Atmospheric Conditions) |

| Secondary Refrigerant | Coolant for Immersion Liquid Cooling Servers (SFM-5016N) | Coolant for Immersion Liquid Cooling Servers(SFM-5016N) |

| Number of secondary side circulation pumps | 1+1 Redundancy | 1+1Redundancy |

| Power Supply Connection | 3ph-380VAC50Hz,5-wire incoming line system(3P+N+PE), Dual power supply Upstream power supply equipped with dual three-phase 32A switches |

3ph-380Vac 50Hz, wire incoming line system(3P+N+PE), Dual power supply Upstream power supply equipped with dual three-phase 63A switches |

| Rated Power Consumption | 4.5kW | 20kW |

| Primary Side Working Fluid | Softened Water, Ethylene Glycol Water Solution | Softened Water, Ethylene Glycol Water Solution |

| Primary Side Permissible Supply Water Temperature | 15~35℃ | 15~35℃ |

| Primary Side Rated Inlet/Outlet Water Temperature Difference | 8℃(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) | 8℃(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) |

| Primary Side Rated Inlet/Outlet Water Temperature | 33/41℃(8℃(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) | 33/41℃(8℃(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) |

| Primary Side Flow Rate | 47.3m³/h;(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) Supports Infinite Adjustment of Flow Rate from 10% to 100% |

71m³/h×2;(Under Standard Atmospheric Pressure, Calculated Based on Softened Water) Supports Infinite Adjustment of Flow Rate from 10% to 100% |

| Primary Side Rated Hydraulic Requirement | 1.2bar, Allowable Pressure Differential for Supply and Return Water from 1.0 to 3.0bar | 1.2bar, Allowable Pressure Differential for Supply and Return Water from 1.0 to 3.0bar |

| Primary Side Connection Way | Two GB/T9119 DN100 PN16-RF Stainless Steel Flanges | Two GB/T9119 DN100 PN16-RF Stainless Steel Flanges |

| Rated Heat Dissipation Power | ≤2.5kW | ≤5kW |

| Working Environment Temperature | 20℃~+40℃ | -20℃~+60℃ |

| Maximum Lifting Dimensions | H2600mm×W680mm×D1300mm | H3400mm×W800mm×D1800mm |

| Maximum Lifting Weight | 2.2t | 5t |

| Human-Machine Interface | 7-inch Color Capacitive Touchscreen | 7-inch Color Capacitive Touchscreen |

| Communication Protocol | Modbus RTU | Modbus RTU |

| Remote Monitoring | Support | Support |

CDM-R-2420FM

CDM-S-21260FM

Immersion Liquid Cooling Server Cabinet

The dedicated computer cabinet for immersion liquid cooling is an important component of the Phase-Change Immersion Liquid Cooling Infrastructure System C8000R-E420. It is specifically designed for high-density deployment with immersion liquid cooling, characterized by a large space and high load-bearing capacity. Both the front and rear doors use a sealed door design, and there is no need for air conditioning inside the cabinet. All the heat loads inside the cabinet are dissipated through the liquid cooling medium. This series of cabinets are 700mm wide and 56U high computer cabinets, with a larger internal space that can accommodate up to 40 immersion liquid-cooled blade servers.

Product Advantages

- 1

- The cabinet is designed with an extended width, capable of accommodating 10 immersion liquid-cooled blade servers horizontally.

- 2

- The cabinet is powered by 380V direct current; it has an integrated DC power supply Busbar.

- 3

- The cabinet has a high load-bearing capacity for equipment, with an effective payload reaching up to 2000kg.

- 4

- The cabinet features a front and rear sealed door design, eliminating the need for internal air conditioning configuration.

| Types | RKS8000B-56UD14W7-L(Left-side Cabinet) RKS8000B-56UD14W7-R(Right-side Cabinet) RKS8000B-56UD14W7-T(Display Cabinet) RKS8000B-56UD14W7(Reserved Cabinet) |

|---|---|

| Frame Dimensions | Includes cabinet frame units, power supply kits, HCDU based on requirements. |

| Includes Components | W700mm×D1400mm×H2600mm(Without Casters) |

| Protection Level | IP00 |

| Material | SGCC(Chassis)+SPCC(Frame)(High-Quality Cold-Rolled Steel |

| Inlet Position | High voltage power cables enter from the bottom (inlet holes are located at the bottom of the cabinet). |

| Outlet Position | Low voltage signal cables exit from the top and bottom (outlet holes are located at the top and bottom of the rear side of the cabinet). |

| Internal Load Capacity | 2000kg |

| Cabinet Net Weight | 450kg |

| Operating Weight | 2000kg |

Rack-Mounted Power Distribution Module (PDM)".

The rack-mounted power distribution module is a power supply component of the Phase-Change Immersion Liquid Cooling Infrastructure System C8000R-E420. It is located at the bottom of the immersion liquid cooling dedicated computer cabinet, providing direct current power supply and operational auxiliary AC power supply for the immersion liquid cooling servers. It serves the functions of power monitoring, circuit breaking, and overcurrent protection for the cabinet's power distribution.

| Types | PDM-DC220 |

|---|---|

| Installation Method | Rack-Mounted Installation |

| Dimensions | H310mm(7U)×W560mm×D1045mm |

| Rated Direct Current Voltage | 380Vdc |

| DC Input Distribution | One Branch or Two Branches |

| Rated Direct Current Power | 220kW |

| AC Input Distribution | 220Vac50Hz, Incoming Line Three-phase system(1P+N+PE) |

| Maximum Input Direct Current | 600A |

| AC Input Current | 20A |

| Current Interruption and Protection Function | Provides rated current breaking capacity and short-circuit protection function. |

| Indicator Lights and Alarms | Equipped with incoming power status indicator lights and working status indicator lights. If the positive and negative poles of the power input are reversed, the buzzer will sound an alarm. |

| Remote Signaling, Remote Measurement, and Remote Control Functions | It can collect the voltage and current of the incoming and outgoing lines; it can collect the opening and closing status of the circuit breakers, high-voltage direct current relays, and the front compartment output fuses; it can control the separation and tripping of micro-circuit breakers through protocols, and this function can be shielded in the hardware. |

| Working Environment Temperature | -20℃~+60℃ |

| PDM Net Weight | 50kg |

Hydraulic Fluid Management and Coolant Circulation Module (HFM)

The Hydraulic Fluid Management and Coolant Circulation Module (HFM) is a prefabricated module for the C8000R-E420, responsible for providing hydraulic control of the heat exchange for the primary side of the phase change liquid cooling CDM, and providing structural support for the immersion liquid cooling infrastructure system.

The control box achieves the control functions of system pressure regulation, liquid supply pressure regulation, and liquid supply temperature regulation, and can also monitor parameters such as system power, system liquid level, and primary side cooling water parameters.

| Types | HFM-W5-F1.9-3W21H15 |

|---|---|

| Frame Dimensions | H1500mm×W2100mm×D1400mm |

| Net weight | 750kg |

| Channel Steel Size | Main Structure Made of 12#A Channel Steel |

| Primary Side Pipeline Inner Diameter | DN100 |

| Primary Side Pipeline Material | 304 Stainless Steel |

| Primary Side Rated Working Pressure | 6bar |

| Primary Side Maximum Allowable Pressure | 10bar |

| Number of Primary Side Filters | 2(One in Use, One on Standby) |

| Mesh Count of the Primary Side Filter Screen | 80目 |

| Secondary Side Rated Refrigerant Flow Rate | 19m3/h |

| Number of Secondary Side Refrigerant Circulation Pumps | 2(One in Use, One on Standby) |

| Secondary side circulation pump, alternating switch way between two pumps. | Automatic Alternation |

| Communication Interface | RJ45-ModbusRTU |

| Electrical Distribution Cabinet | 2 RTU |

| Power Supply Connection | 3ph-380Vac 50Hz,Five-wire incoming line system (3P+N+PE) with dual power supply and automatic switchover |

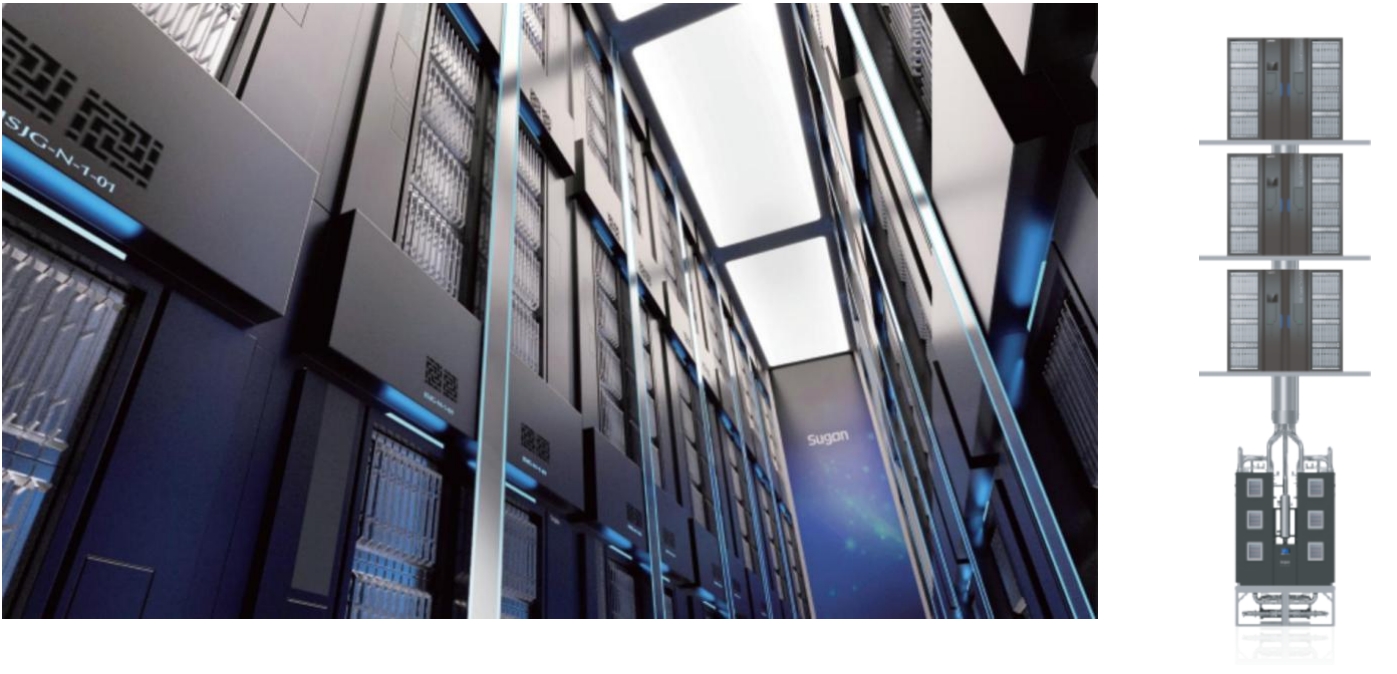

Trinary Integrated Computer Cabinet for Immersion Liquid Cooling

The dedicated trinary integrated computer cabinet for immersion liquid cooling is specifically designed to fit the Silicon Cube and is a key component for server installation, power supply and distribution, and coolant supply and distribution of the Phase-Change Immersion Liquid Cooling Infrastructure System C8000S-E1260.

The left and right sides are the immersion liquid-cooled computer cabinet sub-modules, which provide installation space for the immersion liquid-cooled servers, featuring ultra-strong load-bearing capacity and flexible configuration methods, including cabinet structural units, horizontal liquid distribution and gas return units, power supply kits, etc.

The front middle part is the immersion liquid-cooled cabinet-style power distribution sub-module, which has dual functions of cable tray and complete switchgear. The input cables enter the shaft cabinet from the bottom and are laid up to the upper-level shaft cabinets on both sides. It can support dual direct current inputs and one alternating current input.

The rear middle part is the immersion liquid-cooled cabinet shaft cabinet sub-module, which is internally equipped with gas and liquid return pipelines, recovering the high-temperature coolant generated by the heat dissipation of IT equipment to the CDM. It is also equipped with liquid supply pipelines inside to provide low-temperature liquid coolant to the IT equipment of the computing unit.

| Types | S8000-RDR-1LR(First floor) S8000-RDT(Right Display Cabinet) | S8000-RDR-2LR(Second Floor) S8000-///(Reserved Cabinet) |

S8000-RDR-3LR(Third Floor) |

|---|---|---|---|

| Number of Supported Servers | Up to 80 Servers | ||

| Power Supply Inlet Position | High Voltage Top Inlet (Inlet Hole Located at the Top of the Cabinet) | ||

| Network Outlet Position | Low Voltage Top/Bottom Outlet (Outlet Holes Located on the Rear Top and Bottom of the Cabinet | ||

| Gas Pipe Diameter | DN350×1 | Number of AC/DC Distribution Units | 2 or 1 |

| Liquid Supply Pipe Diameter | DN80×2 | Rated DC Voltage | 380Vdc |

| Pipe Material | 304 Stainless Steel | Rated DC Power | 220kW×2 |

| Number of Liquid Distribution Ports | 24×2 or 24×1 | Max DC Input Current | 600A |

| Type of Fluid Distribution Interface | Interlocking Spill-Proof Quick Connector | AC Input Voltage | 220Vac |

| Number of Gas Return Ports | 4×2 or 4×1 | Max AC Input Current | 20A |

| Cable Entry and Exit ways | Bottom Inlet, Outlet from the Top Side of the Utility Cabinet to the Calculation Cabinets on Both Sides | ||

| Current Break and Protection Features | Provides rated current breaking capacity and short-circuit protection function. | ||

| Indicator Lights and Alarms | Equipped with incoming power status indicator lights and working status indicator lights. | ||

| Remote Signaling, Measurement, and Control Functions | If the positive and negative poles of the power input are reversed, the buzzer will sound an alar It can collect the voltage and current of the incoming and outgoing lines; it can collect the opening and closing status of the circuit breakers, high-voltage direct current relays, and the front compartment output fuses; it can control the separation and tripping of micro-circuit breakers through protocols, and this function can be shielded in the hardware. | ||

| Communication Configuration | The communication method of the acquisition module is RS485 with MODBUS protocol; the acquisition module can communicate with the CDM controller to achieve remote measurement, remote signaling, and remote control functions. | ||

| Auxiliary Functions | 2 sets of four-port national standard 10A five-hole sockets, providing 220V AC single-phase electricity for use by debugging and maintenance personnel. | ||

| Operating Environment Temperature | -20℃ ~+60℃ | Internal Load Capacity | 4000kg |

| Frame Dimensions | W2350mm×D1500mm×H2350mm | Cabinet Net Weight | 1400kg |

| Materials | SGCC(Chassis)+SPCC(Racks) | Operating Weight | 4550kg |

Auxiliary Equipment for Immersion Liquid Cooling

System Pressure Stabilization Unit:

Sugon C8000 series phase-change liquid cooling dedicated auxiliary equipment, stable operation, highly efficient and reliable, meeting the daily operation pressure stabilization and exhaust requirements of the CDM. Integrated design with unified vacuuming and condensation functions.

Movable Charging and Liquid Displacement Unit:

Sugon C8000 series phase-change liquid cooling dedicated auxiliary equipment, used for liquid charging and maintenance replenishment during the implementation of the phase-change liquid cooling infrastructure system, including a self-priming charging and displacement pump for the dedicated cooling fluid of immersion servers. The tool vehicle integrated design offers a more relaxed and convenient experience for data ceter room use.

Charging and Liquid Displacement Cart:

Sugon C8000 series phase-change liquid cooling dedicated auxiliary equipment, used for liquid charging and maintenance replenishment during the implementation of the C8000 series phase-change liquid cooling infrastructure system, meeting all daily maintenance requirements for blade severs liquid displacement and CDM replenishment. The tool vehicle integrated design offers a more relaxed and convenient experience for data center room use.

Coolant for Immersion Liquid-Cooled Servers

SLIQUID GLOBAL SFM-5016N Electronic Fluorinated Fluid is the core raw material for phase-change immersion servers, and has the following advantages: environmentally friendly and non-toxic; it has low viscosity; strong compatibility, does not react with electronic components, printed circuit boards, metals, and most common materials; and it is highly safe, with good thermal stability, an ODP (Ozone Depletion Potential) value of zero, a short atmospheric lifetime, no ozone depletion, and a low greenhouse effect value.

| Basic Parameters | |

|---|---|

| Density | 1600 kg/m³ |

| Relative dielectric constant | <2 |

| Viscosity | 0.59mm2/s |

| Thermodynamic Parameters | |

| Specific Heat | 113KJ/kg |

| Enthalpy of Vaporization | 85KJ/kg |

| Boiling Point | ~50℃ |

| Toxicity Parameters | |

| InhalationLC50 | >20mg/L |

| Skin LD50 | >5000mg/kg |

| IngestionLD50 | >5000mg/kg |

| Environmental Parameters | |

| ODP | >20mg/L |

| GWP | >25 |